Hydraulic Sales & Service in Caboolture

- Clear diagnosis with straight to the point solutions

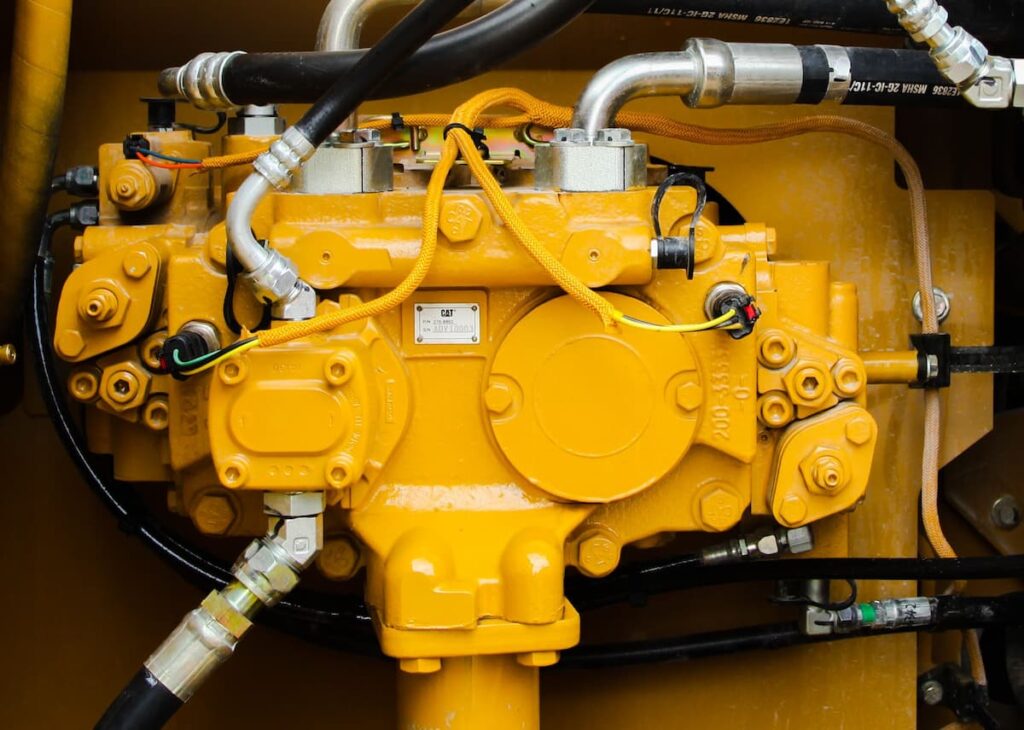

- Cylinders, hoses, pumps, motors and onsite repairs

- Workmanship you can rely on every time

- Located 14 Commercial Dr, Caboolture QLD 4510

Send Your Repair Request Using the Form Below

call us for same day service

FIND US AT 14 COMMERCIAL DR, CABOOLTURE, QLD, 4510

The Services That Stop the Downward Spiral

Hydraulic Parts & Oil

Local stock in Caboolture means you aren’t waiting days for a part that could get you back on site today.

Hydraulic Cylinder Repairs

Leaking, drifting, or losing pressure? A failed seal may score the rod and lead to a full cylinder replacement. Fix it early to avoid the bigger bill.

Hydraulic Hose Repairs & Replacements

Get hoses repaired or replaced to restore safe, reliable hydraulic flow and reduce unexpected downtime.

Hydraulic Pumps &

Motors

When pumps and motors fail, they take the whole system with them. Proper diagnosis may save you thousands.

When Your Hydraulics Stop… Everything Stops

It always begins the same way.

A small leak. A hose that looks a bit worn. A cylinder that drifts more than it used to.

Easy to ignore until suddenly, the machine that runs your farm, job site, or livelihood refuses to work.

And when it stops, your entire day stops with it.

That’s where Caboolture Hydraulics steps in your local hydraulic specialist, right here in Caboolture.

For an overview of everything we offer, visit our Services page.

Here’s Where Things Turn Around

Once your machine arrives at the workshop, everything starts moving in the right direction:

- The fault is diagnosed accurately no band aid fixes

- You get clear options repair or replace, with honest explanations

- Parts are sourced or repaired often from stock already on the shelf

- Your equipment goes back to work — properly tested and ready for load

This is the point where downtime stops costing you money…

And productivity starts paying you again.

One Breakdown Becomes One Big Problem…

Unless You Fix It Fast

A simple hydraulic fault may turn into:

- A tractor that loses pressure halfway through a job.

- A Bobcat stuck mid-project.

- A farm machine that keeps costing money every hour it sits idle.

- A hose burst that becomes a full hydraulic failure.

The longer you leave it, the more damage it may cause and the more expensive the fix may become.

That’s why locals head straight to a workshop that specialises in hydraulics…

Not a general mechanic.

Not someone “who’ll have a look”.

A hydraulic expert.

The Local Workshop That Keeps Your Machinery Working

The Local Workshop That Keeps Your Machinery Working

No guesswork.

No runaround.

No sending parts to Brisbane.

Just practical, hands-on hydraulic repairs right here in Caboolture designed to get your gear back to work quickly and without confusion.

From tractors to excavators, pumps to cylinders, hoses to motors, everything is inspected properly so you understand exactly what’s gone wrong… and the smartest way to fix it.

Why Locals Choose Caboolture Hydraulics

People don’t come here by accident.

They come because of Geoff, the tradesman who built his reputation on being straight-up, thorough, and fair.

And with almost no hydraulic specialists in Caboolture, machinery owners rely on someone who actually understands hydraulics from the inside out… not someone who “has worked around them”.

Farmers, earthmovers, contractors, and long-time customers from his previous workshop all trust Geoff because:

- He tells you the truth about repair vs replacement

- He stands behind his work

- He remembers you and your machines

- He treats your downtime like it matters

Because it does.

Let’s Stop the Downhill Slide Now

Your machinery is too important to your work to leave a hydraulic fault until it gets worse.

A quick phone call is often all it takes to stop:

- Lost time

- Lost Pressure

- Lost Income

And set your equipment on the right path again, repaired, reliable, and ready.

Hydraulic FAQ – Caboolture Hydraulics

What is the main purpose of hydraulics?

Hydraulics allow machines to lift, push, pull and move heavy loads using pressurised fluid.

They create strong, smooth, controlled force in equipment like tractors, excavators, Bobcats, forklifts, farm machinery and industrial tools.

Anywhere you need reliable power, hydraulics make the work easier and more efficient.

What is the most common problem in a hydraulic system?

The most frequent issues include:

- Leaking seals

- Worn or damaged hoses

- Low hydraulic oil levels

- Contaminated or incorrect oil

- Failing pumps or motors

- Cylinder drift or loss of pressure

Most hydraulic faults come from wear, poor maintenance, or small leaks that gradually get worse.

What tests would you perform on a hydraulic system?

Depending on the fault, a hydraulic specialist may carry out:

- Pressure testing

- Leak testing

- Cylinder bypass tests

- Pump and motor flow tests

- Visual inspections (hoses, fittings, seals, oil, connections)

These tests help narrow down the true cause of the problem before repairs begin.

How do you diagnose hydraulic problems?

A proper hydraulic diagnosis usually includes:

- Asking about symptoms (slow movement, no power, noise, leaks, drifting, heat)

- Inspecting the machine or component

- Checking oil condition

- Performing pressure, flow or bypass tests

- Tracing the fault to the exact part

Diagnosis is about finding the real issue, not the visible symptom.

What will happen if there is air trapped in the hydraulic system?

Air in a hydraulic system may cause:

- Jerky or uneven movement

- Loss of pressure

- Slow or weak operation

- Noise and vibration

- Foaming hydraulic oil

- Faster wear on pumps and valves

Bleeding the system and fixing the source of the air resolves the issue.

What does “hydraulic” mean

The word hydraulic refers to the use of pressurised fluid to create movement or force.

In machinery, hydraulics allow heavy loads to be lifted, pushed, turned or held in place using oil under pressure.

Any time a machine uses fluid power to operate a ram, pump, motor or attachment, it is using hydraulics.

How does hydraulic work

A hydraulic system works by trapping oil inside a sealed system and pressurising it.

When the operator moves a control, the pump pushes oil through hoses and valves into a cylinder or motor.

Because oil cannot be compressed, it transfers force instantly, allowing the machine to lift, tilt, steer or move with power and precision.

This is why hydraulics are used on tractors, excavators, loaders, slashers, attachments and industrial equipment.

How do you adjust the pressure on a hydraulic system

Hydraulic pressure is controlled through the machine’s valves and relief settings.

If pressure is incorrect, a hydraulic specialist may adjust or service the system so it operates safely within its designed range.

Pressure should never be changed casually because incorrect settings may damage cylinders, pumps, motors or hoses and may create unsafe operating conditions.

If your machine feels weak, is running hot or is not lifting as it should, a technician may inspect the system to find the true cause rather than adjusting pressure blindly.

Call Caboolture Hydraulics Today

Or send an enquiry to book your hydraulic inspection at the Caboolture workshop.

Your work depends on your hydraulics.

And your hydraulics depend on getting the right help before things slide any further.