Hydraulic Equipment Caboolture

- Repairs and servicing for all hydraulic equipment

- Fast diagnosis to restore pressure, performance and safety

- Trusted hydraulic specialist for operators across Caboolture and Moreton Bay

Contact us for quick advice and product availability

call us for same day service

FIND US AT 14 COMMERCIAL DR, CABOOLTURE, QLD, 4510

When Hydraulic Equipment Starts to Fail… Everything Slows Down

Hydraulic equipment may look tough, but most failures begin quietly. A cylinder starts drifting, a pump takes longer to build pressure, a hose looks dry, or a fitting begins to seep. These are easy to ignore when the machine is still moving, but hydraulics operate under extreme pressure. A small drop in performance is often the first sign of a deeper fault building underneath.

Once one hydraulic component begins to struggle, the rest of the system feels it. Hydraulics rarely fail all at once—issues typically escalate in a chain reaction, where heat, contamination and pressure loss spread damage to other components.

Common ways failure shows up:

Slow, weak or jerky movement (inconsistent pressure or flow)

Attachments refusing to lift (stalling mid-lift or failing to operate)

Overheated hydraulic oil (rapid seal wear, reduced lubrication, contamination spread)

Leaks that spray under pressure (dangerous high-pressure bursts and rapid oil loss)

Full equipment shutdown (loss of steering, lifting and attachment function)

That is why operators across the Moreton Bay region rely on Caboolture Hydraulics to diagnose and repair issues early—before a minor fault becomes a major repair.

Our Core Hydraulic Services Include

Hydraulic Cylinder Repairs

Leaking, drifting, or losing pressure? A failed seal may turn into a scored rod… which may turn into a full cylinder replacement. Fixing it early saves you from the expensive end of the slope.

Hydraulic Hose Repairs and Replacements

A burst hydraulic hose can shut your job down instantly and may cause further damage if not replaced correctly. We supply and fit new hoses and fittings, check for rubbing points, pressure issues or underlying causes and ensure your machine returns to safe operation with proper hose routing and protection.

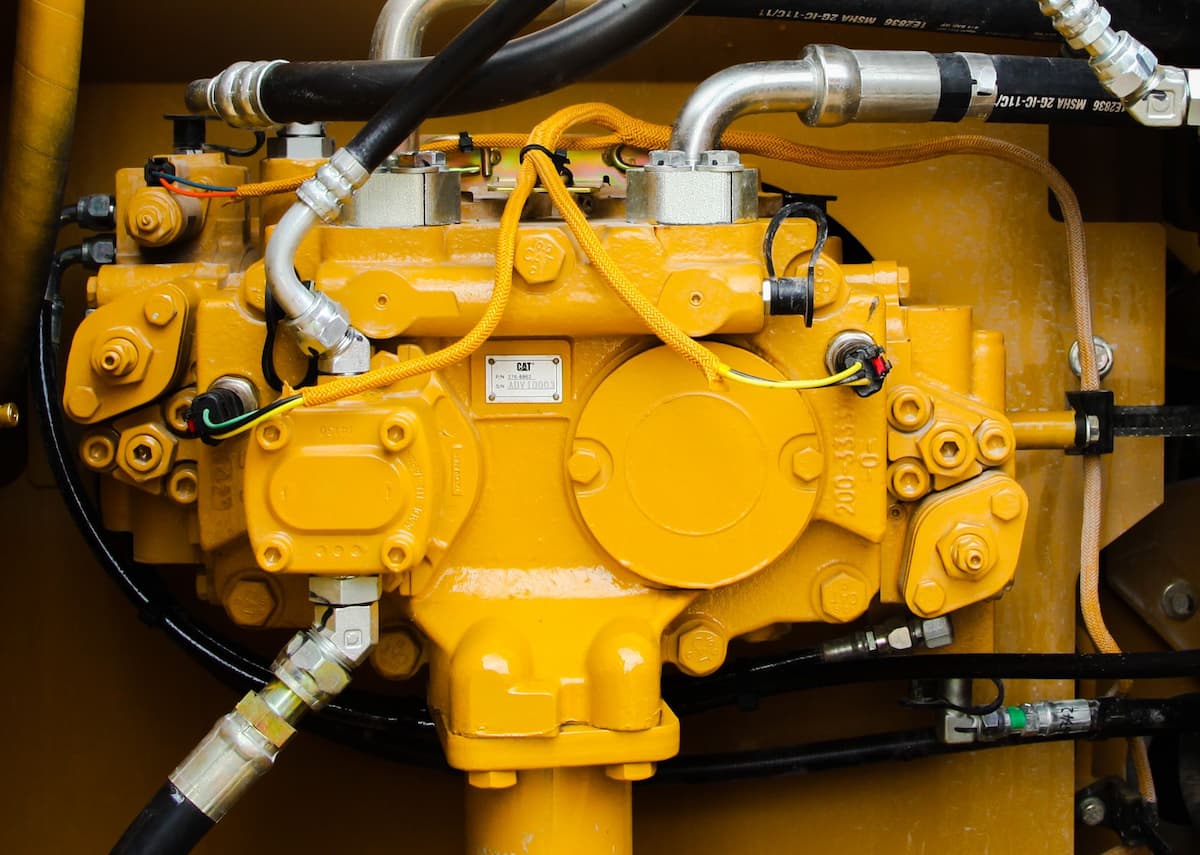

Hydraulic Pump Repairs

When a pump begins to fail your entire machine feels it slow hydraulics, weak lift, heat build up and pressure loss. We diagnose pump performance through flow and pressure testing, strip and assess worn components and repair or replace pumps based on what makes the most financial sense.

Hydraulic Motor Repairs

Hydraulic motors drive movement and rotation in machinery such as wheels, attachments and implements. Slow turning, vibration or loss of torque often indicate internal wear. We test, dismantle and evaluate motors to identify faults early and restore reliable power output.

Hydraulic Diagnostics and Testing

Most hydraulic issues look the same on the outside. Only proper testing reveals the real cause. Our diagnostic process includes pressure tests, flow tests, bypass tests, leak checks and oil contamination assessments, giving you a clear explanation of what is actually happening inside your system.

Hydraulic Oil, Parts and Components

To reduce downtime, we stock a growing range of hydraulic parts in the Caboolture workshop including seal kits, hoses, fittings, cylinders, pumps, motors and high grade hydraulic oil. If a part is not on hand, we advise the fastest sourcing option so your machinery returns to work as soon as possible.

Hydraulic Equipment We Work On

Hydraulic systems power almost every major movement on modern machinery.

We repair and service hydraulic equipment used across a wide range of industries, including farming, earthmoving, civil construction, landscaping and industrial operations.

Tractors

Hydraulics power loaders, three point linkages, steering, remotes and implements. A single weak hydraulic component may stop an entire workday on the farm.

Excavators

Booms, sticks, buckets and auxiliary attachments all depend on high pressure hydraulic systems. Even a minor fitting leak or pump issue may shut down digging entirely.

Bobcats and skid steers

Oil changes, filter replacement, seal replacement, leak checks and system maintenance to prevent future failures.

Loaders and backhoes

Constant lifting and repetitive heavy movements place enormous stress on pumps, cylinders and hoses. Proper hydraulic function is essential for safe operation.

Slashers and agricultural implements

Hydraulic adjustments, top links and auxiliary lines must hold pressure reliably or the attachment may fail during work.

Industrial equipment

Presses, compactors, tail lifts and workshop machinery depend on stable hydraulic pressure. Any leak or pressure drop may stop production.

Farming machinery

Sprayers, harvesters, feedout machines and tractors rely on consistent hydraulic flow to perform essential seasonal tasks.

Civil and council equipment

Road maintenance machinery, mowers, trenchers and specialised vehicles require dependable hydraulics to stay on schedule and avoid community delays.

Transport and utility machinery

Tipper trucks, cranes, loaders, tail lifts and service vehicles all rely on hydraulics for lifting, tilting and load handling.

Common Problems With Hydraulic Equipment

Why Hydraulic Equipment Fails (And Why the Damage Spreads Fast)

Hydraulic equipment failures are rarely isolated, because the same oil that powers the system also carries whatever is causing the damage. Common triggers include oil contamination (dirt, water, or metal fragments circulating through cylinders, pumps, valves, and motors), pressure spikes that loosen fittings and blow hoses or seals under load, and heat from overworking that thins oil, reduces lubrication, and rapidly degrades components.

Ageing hoses and seals also contribute as rubber hardens, cracks, and loses flexibility, leading to leaks and unsafe pressure loss, while incorrect routing or installation (poor hose angles or unsupported lines) places extra strain on fittings and connections. Running low on hydraulic oil is another major cause, as it starves pumps, burns motors, and damages internal surfaces. Once the damage starts, it tends to spread quickly through the entire system, which is why accurate diagnosis is the most reliable way to stop the chain reaction.

Hydraulic Equipment Problems

Hydraulic equipment often shows early symptoms before a full breakdown. We regularly help operators dealing with:

- Slow, weak or delayed hydraulic movement

Often caused by pump wear, leaking fittings or internal bypassing in cylinders. - Hydraulic oil leaks

From hoses, fittings, seals or pipes. Even small leaks may escalate rapidly under load. - Overheating hydraulic systems

Usually caused by contamination, pump wear or incorrect hydraulic flow. - Noisy hydraulics

Whining, rattling or chattering may indicate cavitation or pump starvation. - Pressure loss under load

A sign that hydraulic equipment cannot hold pressure and is beginning to fail internally. - Cylinder drift or unexpected movement

Often caused by worn seals, damaged rods or internal leakage. - Attachment failure or slow operation

Hydraulic equipment may be struggling to deliver enough flow or pressure to run implements.

The sooner these symptoms are diagnosed, the easier — and more cost effective — the repair becomes.

What hydraulic parts can we work on?

- Two wire and four wire hoses

Used in light, medium and heavy duty hydraulic systems. These hoses must withstand extreme pressure cycles without weakening or bursting. - High pressure and return hoses

Pressure lines deliver force while return lines bring fluid back to the tank. Both must be sealed correctly or the entire system becomes unstable. - Steel hydraulic piping

Used in high heat areas or tight spaces where rubber hoses may not survive. Steel pipes require precise bending, sealing and installation. - JIC, ORFS, BSP, NPT and metric fittings

These thread and sealing types vary across machinery brands. Selecting the wrong fitting may cause leaks, thread damage or pressure loss. - Straight, swivel and angled fittings

Correct fitting angles ensure hoses do not rub, kink or strain during movement. Poor routing is one of the top causes of early failure. - Hydraulic pumps, motors and cylinders

The core components of hydraulic power. Weakness in any one of these may damage the entire system if not repaired early. - Filters, valves and couplings

These regulate flow and protect the system from contamination. A blocked filter or worn valve may cause slow movement and overheating. - All hydraulic components used across Australian machinery

Whether it is a common agricultural fitting or a hard to source industrial part, we repair, replace or correctly match components to keep your machine performing reliably.

If your hydraulic equipment is not listed, we repair it. Hydraulic systems all follow the same principles — and we work on virtually every system used in Australia.

Why Choose Caboolture Hydraulics

- Local workshop with fast turnaround – No driving to Brisbane or the Sunshine Coast. Repairs are completed here in Caboolture.

- Accurate testing to prevent unnecessary spending – We confirm the real cause before any repair begins.

- High quality hydraulic components stocked locally – Seal kits, hoses, fittings, hydraulic oil and pumps kept on hand for faster repairs.

- Decades of hands on hydraulic experience – Geoff has repaired hydraulic equipment across farming, earthmoving, landscaping and industrial sectors for decades.

- Trusted across Caboolture and Moreton Bay – Operators rely on us because we explain the issue clearly and repair it properly.

Our Hydraulic Equipment Repair Process

Step 1.

Contact and Initial Discussion

Explain the symptoms. Photos and videos help speed up diagnosis.

Step 2.

Bring the Equipment or Component

Machines or individual components such as cylinders, pumps or hoses may be dropped off.

Step 3.

Testing and Diagnosis

We run flow tests, pressure tests and contamination checks to find the cause.

Step 4.

Repair or Replacement

Work proceeds based on the most practical, long lasting and cost effective solution.

Step 5.

Testing and Return to Work

Your hydraulic equipment is tested under load to ensure it performs reliably.

Hydraulic Equipment FAQs

What is hydraulic equipment?

Any component that creates, controls or delivers hydraulic power including pumps, cylinders, motors, hoses, valves and piping.

Do you repair all hydraulic equipment?

Yes. We repair hydraulic equipment used in farming, earthmoving, landscaping, civil, industrial and council machinery.

Do you offer hydraulic servicing as well as repairs?

Yes. We provide complete hydraulic servicing including oil changes, seal replacement, leak checks and preventative maintenance.

Can hydraulic equipment be repaired quickly?

Repairs are often fast when parts are in stock. Early diagnosis prevents delays.

Do you stock hydraulic components?

Yes. We keep seal kits, hoses, fittings, hydraulic oil, valves and related components in the Caboolture workshop.

Book Your Hydraulic Equipment Repair

A hydraulic problem will not fix itself.

The longer it continues, the more damage it may cause to pumps, motors, cylinders and attachments.