Hydraulic Services Caboolture

- Complete hydraulic repairs for all machinery

- Fast diagnosis to reduce downtime

- Trusted local specialist serving Caboolture and Moreton Bay

- Located 14 Commercial Dr, Caboolture QLD 4510

Send Your Repair Request Using the Form Below

call us for same day service

FIND US AT 14 COMMERCIAL DR, CABOOLTURE, QLD, 4510

When One Hydraulic Problem Starts… Everything Else Follows

It always starts the same way.

A cylinder that drifts.

A hose that looks a bit worn.

A pump that sounds louder than it used to.

Easy to ignore, until the moment it is not.

Because when hydraulics fail, work does not just slow down…

It stops instantly, completely, and often at the worst possible time.

That is when machinery owners across Caboolture turn to Caboolture Hydraulics.

Not because we are the closest workshop.

But because we know what downtime means, missed deadlines, pressure on the farm, jobs piling up, customers waiting and money draining away by the minute.

Our Core Hydraulic Services Include

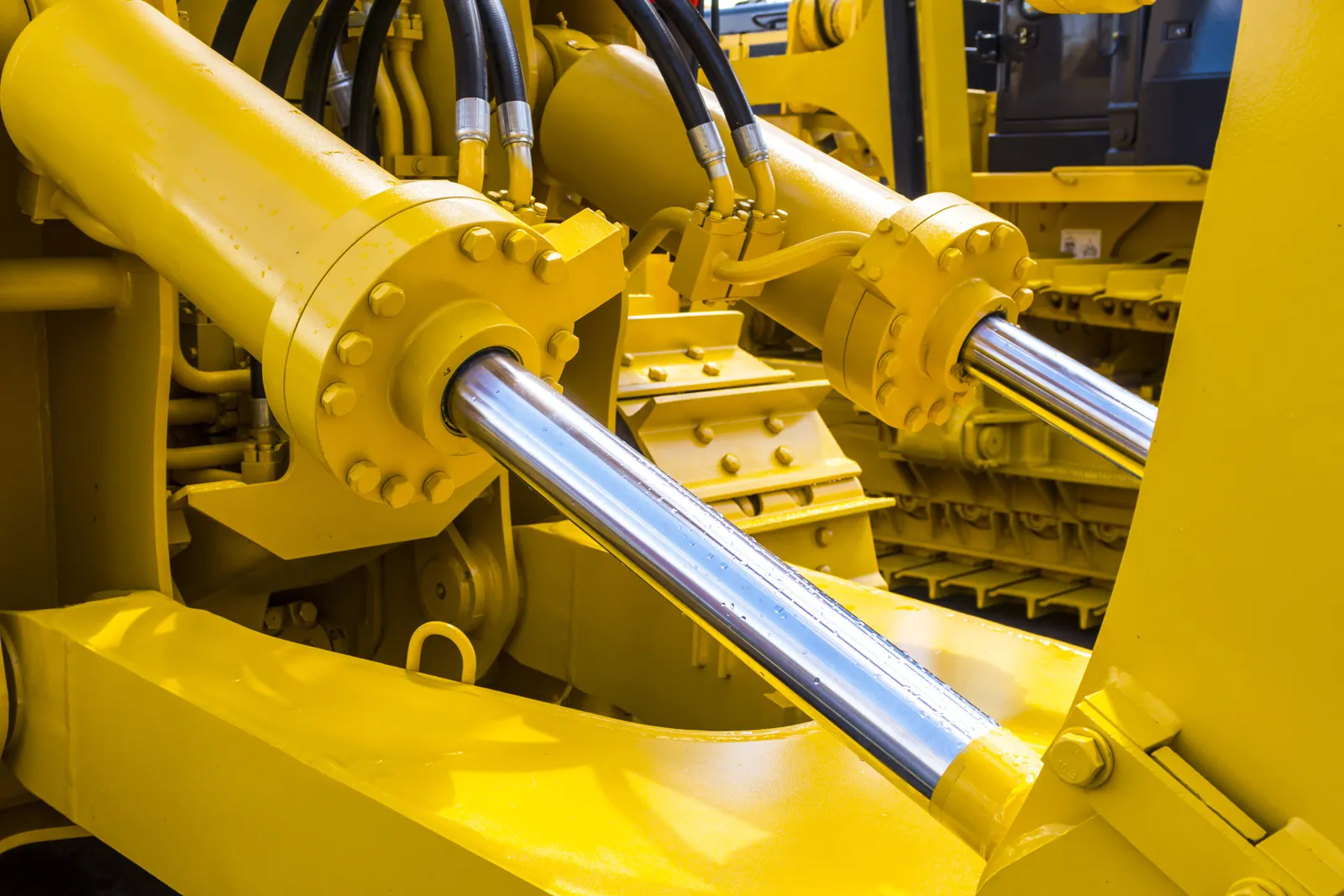

Hydraulic Cylinder Repairs

Leaking, drifting, or losing pressure? A failed seal may turn into a scored rod… which may turn into a full cylinder replacement. Fixing it early saves you from the expensive end of the slope.

Hydraulic Hose Repairs and Replacements

A burst hydraulic hose can shut your job down instantly and may cause further damage if not replaced correctly. We supply and fit new hoses and fittings, check for rubbing points, pressure issues or underlying causes and ensure your machine returns to safe operation with proper hose routing and protection.

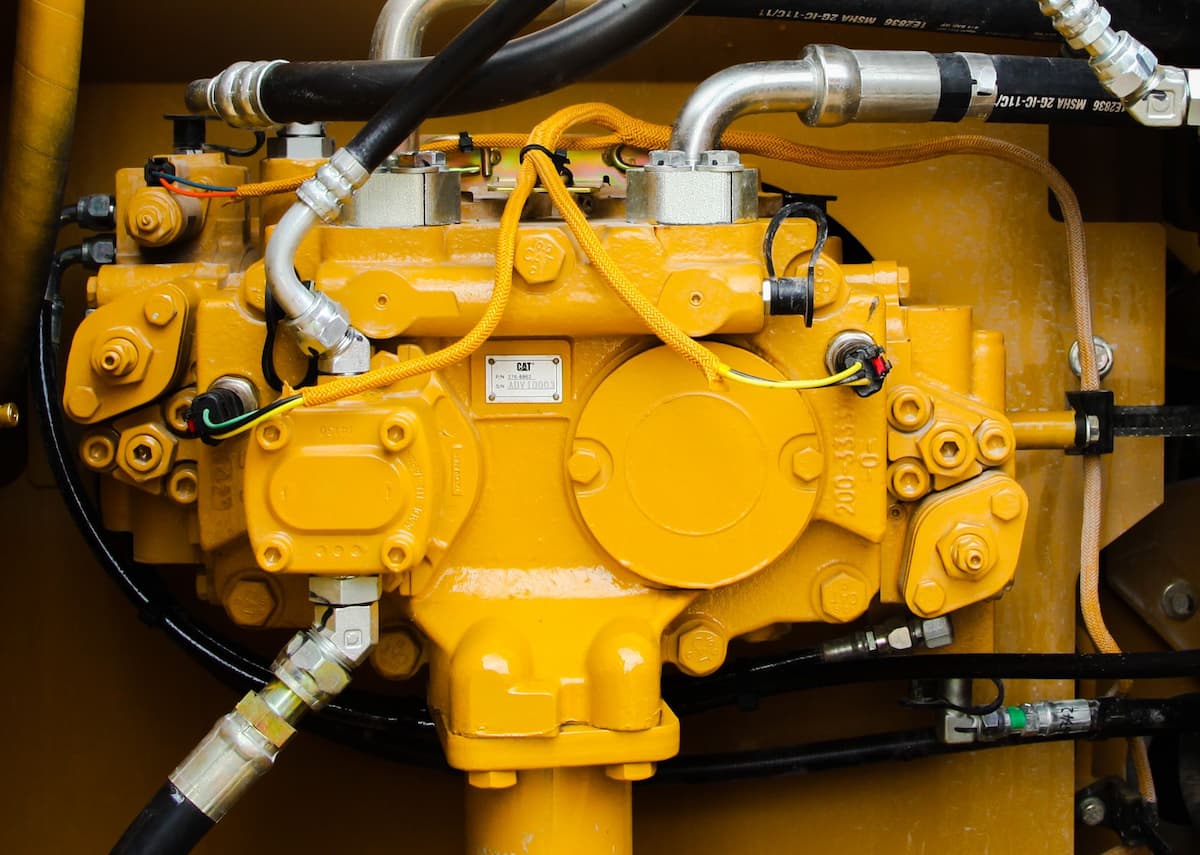

Hydraulic Pump Repairs

When a pump begins to fail your entire machine feels it slow hydraulics, weak lift, heat build up and pressure loss. We diagnose pump performance through flow and pressure testing, strip and assess worn components and repair or replace pumps based on what makes the most financial sense.

Hydraulic Motor Repairs

Hydraulic motors drive movement and rotation in machinery such as wheels, attachments and implements. Slow turning, vibration or loss of torque often indicate internal wear. We test, dismantle and evaluate motors to identify faults early and restore reliable power output.

Hydraulic Diagnostics and Testing

Most hydraulic issues look the same on the outside. Only proper testing reveals the real cause. Our diagnostic process includes pressure tests, flow tests, bypass tests, leak checks and oil contamination assessments, giving you a clear explanation of what is actually happening inside your system.

Hydraulic Oil, Parts and Components

To reduce downtime, we stock a growing range of hydraulic parts in the Caboolture workshop including seal kits, hoses, fittings, cylinders, pumps, motors and high grade hydraulic oil. If a part is not on hand, we advise the fastest sourcing option so your machinery returns to work as soon as possible.

Ignoring a Hydraulic Problem Does Not Freeze It… It Accelerates It

Hydraulic systems rarely fail all at once. They give warnings. Subtle ones until they become expensive fast.

Here are the issues we see every week in the Caboolture workshop:

Machinery losing lifting power

Often caused by worn pumps, internal cylinder leakage or low hydraulic pressure. When lifting power drops, the machine may struggle under load or fail to lift altogether.

Cylinders drifting under load

A drifting cylinder usually indicates worn seals or internal bypassing, meaning hydraulic pressure is bleeding past the piston instead of holding the load steady.

Burst hydraulic hoses

A hose failure stops the job immediately and may be caused by abrasion, pressure spikes, age, or incorrect hose routing. This is one of the most common emergency breakdowns we see.

Hydraulic oil contamination

Dirty or contaminated oil can damage pumps, valves, motors and cylinders. It often occurs from water ingress, degraded seals or lack of oil changes, and may cause premature system failure.

Pumps and motors overheating

Heat is a sign of inefficiency or internal wear. Overheating pumps or motors may lose power, slow down or seize if the issue is not addressed early.

Pumps and motors overheating

Pressure loss may come from leaking lines, worn pumps, internal bypassing or valve issues. This results in weak or slow hydraulic function across the machine.

Jerky or slow hydraulic movement

Usually caused by air in the system, low oil, contamination or a failing pump. Jerky motion is often the first warning sign something is going wrong internally.

Noisy hydraulic operation

Excessive noise — such as whining, grinding or rattling — may indicate cavitation, low oil, aeration or component wear. Noise is often an early sign of pump damage.

Internal bypassing in cylinders

When a cylinder bypasses internally, oil slips past the piston instead of creating force. This leads to drifting, weak lifting and inconsistent movement.

When machines behave like this, they are telling you something is wrong internally.

That is when a proper diagnosis matters, not guesswork.

The Slide Begins With One Fault

Here Is What We Repair Before Things Get Worse:

Most hydraulic issues do not stay small. A minor leak becomes a pressure loss. A worn seal becomes a blown cylinder. A weak pump becomes a seized motor.

That is why we offer complete hydraulic services for machines large and small, including tractors, Bobcats, excavators, skid steers, slashers and farm equipment.

Hydraulic Diagnostics

and Testing

Most hydraulic failures look identical at first. Slow movement could be a cylinder bypass, a failing pump, contaminated oil or a valve issue. The only way to know for sure is proper hydraulic testing.

Testing may include:

Pressure tests

Pressure testing shows whether the hydraulic system is producing the correct amount of force. If pressure is too low, the machine may struggle to lift, move slowly or lose power under load. This test helps identify issues with pumps, valves, relief settings or internal leakage.

Flow tests

Flow testing measures how much hydraulic oil is moving through the system. Even if pressure looks normal, low flow may cause slow or jerky operation. This test helps pinpoint worn pumps, clogged filters, restricted lines or failing motors.

Cylinder bypass tests

Bypass testing checks whether oil is leaking internally past the piston inside a cylinder. When internal bypass occurs, cylinders drift, drop under load or lose strength. This test confirms whether the issue is inside the cylinder rather than elsewhere in the hydraulic system.

Leak detection

Leak detection involves tracing external oil leaks and internal pressure losses. Even small leaks may lead to major failures, air entering the system or dangerously low oil levels. Finding leaks early prevents sudden hose bursts, pump damage and contamination.

Oil contamination checks

Contaminated oil may cause rapid wear, overheating, sticking valves and pump failure. We check for water, dirt, metal fragments and breakdown of old oil. Identifying contamination early helps prevent major component damage and ensures smoother, safer operation.

Accurate diagnosis prevents wasted money and unnecessary work.

The Real Problems Our Hydraulic Services Solve

Hydraulic breakdowns do not just interrupt work — they ripple through every part of your operations. On farms, a single hydraulic issue may stall planting, spraying, or harvesting. When machinery stops during time-sensitive work, entire crop cycles may be affected and productivity drops straight away. On civil, landscaping, and construction sites, downtime may halt progress for the whole team. Schedules blow out, subcontractors wait around, and multiple jobs get pushed back.

Every hour a machine sits idle costs money. Operators cannot bill for work they cannot complete, so even a small hydraulic failure may quickly become an expensive setback. Delays also put deadlines at risk — clients expect jobs finished on time, and equipment failure may affect contracts, reduce trust, or force reschedules.

Running machinery with weak pressure, drifting cylinders, or contaminated oil may cause further internal damage. What starts as a minor issue may escalate into a major repair if left untreated, often leading to unexpected repair bills. A simple seal issue may become a rod replacement, a mild pump problem may become a full rebuild, and a cheap hose fix may lead to internal contamination. Many major failures begin with a small problem ignored for too long. These services help stop that downward slide by restoring safe, reliable hydraulic performance.

Why Caboolture Hydraulics Becomes The Place I Always Go Now

Local Workshop Less Travel More Productivity

No need to drive to Brisbane or the Sunshine Coast. Your hydraulic specialist is right here in Caboolture.

Experienced Diagnosis Decades of Hands On Knowledge

Geoff has repaired hydraulics across tractors, earthmoving machinery and industrial equipment for decades.

Learn more about him on our About Us page.

Honest Advice Repair or Replace Based on What Makes Sense

If repairing is not worth it, we tell you.

If replacing prevents further cost, we explain why.

Fast Turnaround When Parts Are Available

Local parts mean faster repairs and less downtime.

Trusted by Farmers Contractors and Machinery Owners

Our reputation is built on accuracy, reliability and integrity.

See the industries we support on the Industries page.

Hydraulic Parts and Oil in Stock

Parts delays are one of the biggest causes of extended downtime. That is why we keep commonly used hydraulic components in the Caboolture workshop, including:

Hydraulic cylinders

Cylinders are responsible for lifting, pushing, tilting and steering functions across tractors, earthmoving equipment and farm machinery. When a cylinder leaks, drifts or loses power, the entire machine may become unsafe or unusable. Keeping replacement cylinders and rebuild components on hand allows us to get machines back up and running far sooner than shops that need to order parts in.

Seal kits

Seal kits contain the internal seals, O-rings and wipers that stop oil from leaking inside a cylinder or pump. When these seals fail, machines may lose pressure, drift under load or leak hydraulic oil. Having the correct seal kits in stock means many repairs can be completed the same day rather than waiting days for parts to arrive.

Hoses and fittings

Hydraulic hoses and fittings carry pressurised oil throughout the entire system. If a hose bursts or a fitting fails, the machine stops immediately and often loses a significant amount of hydraulic oil. By stocking common hose sizes, fittings and connectors, we can replace damaged lines quickly and safely, preventing further damage and unnecessary downtime.

Hydraulic pumps and motors

Pumps and motors generate the power and movement required for lifting, driving attachments and running implements. When these components wear out, machines may run slowly, lose lifting power or overheat. Having pumps and motors readily available for assessment, repair or replacement allows us to restore full performance without long delays.

Hydraulic oil for tractors and machinery

High-quality hydraulic oil is essential for cooling, lubrication and smooth system operation. Contaminated or incorrect oil can lead to rapid wear, overheating, seal failure and major component damage. By keeping the right oil for tractors, loaders, excavators and farm machinery in stock, we help operators maintain their machines properly and avoid preventable breakdowns.

How the Process Works

Step 1.

Contact and Initial Discussion

Start via the Contact Us page. Send photos or videos if you can.

Step 2.

Bring Your Machine or Part to the Workshop

Bring the whole machine or just the faulty part such as a cylinder, pump, motor or hose.

Step 3.

Diagnosis and Explanation

We show you what is happening inside the system and present your best options.

Step 4.

Repair or Replacement

Work proceeds based on the most cost effective and long lasting solution.

Step 5.

Testing and Return to Service

Machines and components are tested before they leave the workshop to ensure they are ready for real work.

FAQs About Our Hydraulic Services

What do hydraulic services include

What is a hydraulic service

A hydraulic service involves diagnosing and repairing hydraulic components to ensure your machine operates safely and reliably.

How much does it cost to fix hydraulics

Do hydraulics require maintenance

Ready to Stop the Downward Slide

When your machinery is drifting, losing pressure, leaking or refusing to move, the solution starts with one step.